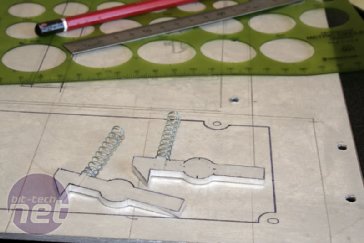

Now it was time to think about exactly how the chassis would roll out of the shell, and what fixings needed to be made. I decided the rails that the chassis would roll on would have a slight incline and the chassis would be fixed to the shell with two spring loaded catches. When the catches were released, the chassis would slide out under gravity.

The pictures below are of this part being made, but eventually the idea was thrown out, so a lot of time was lost and a new back-plate had to be made.

In the mean time, another small panel was cut to house the switch and front panel I/O box.

To mount the switch and I/O panel on the front, an opening had to be cut into the floating lower panel, in order to make way for this boxes depth.

Also an opening needed to be cut into the front panel, which went together like this:

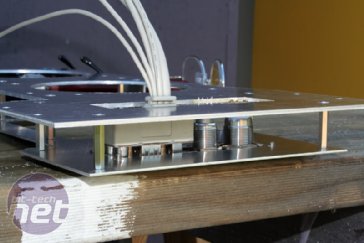

The bottom of the case was cut, bent, and a large area was removed for ventilation.

The pictures below are of this part being made, but eventually the idea was thrown out, so a lot of time was lost and a new back-plate had to be made.

In the mean time, another small panel was cut to house the switch and front panel I/O box.

To mount the switch and I/O panel on the front, an opening had to be cut into the floating lower panel, in order to make way for this boxes depth.

Also an opening needed to be cut into the front panel, which went together like this:

The bottom of the case was cut, bent, and a large area was removed for ventilation.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.